Who We are ?

-------A professional PCBA, Charging Locker manufacturer and

solution provider.

Betterliv Technology Co., Ltd is a professional manufacturer

and exporter of PCBA and Charging Locker. It is a

reliable and trusted supplier. As WPC member, most of products has

passed QI,CE,Rohs,FCC. With the concept “smart, health &

taste”, we built the product line for charging lockers and PCBA

products. We have a strong technical team, design team and

production capacity. We have an independent SMT production line and

reliability test equipment laboratory.

In pursuit of our vision to become a preferred choice of better

living experience, a new lifestyle to our customers, and our

mission to improve the quality of people’s lives, we leverage the

innovative talents to design and develop the innovative and

user-friendly products. And we differentiate ourselves from those

competitors on a basis of forward thinking, open and market-driven

mindset.

We embrace the values of of customer satisfaction, operational

excellence and innovation provide our customers with satisfying

deliverables.

What products we do?

------- Produce and customize various PCBA and Charging Locker.

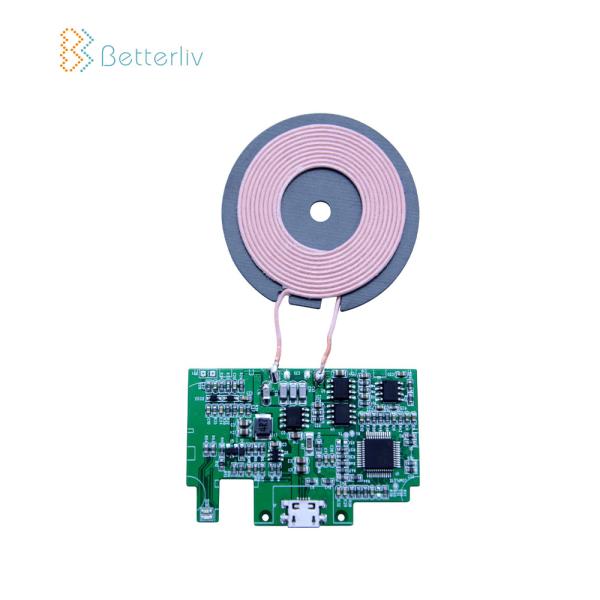

Power PCBA

Wireless charger PCBA

Bluetooth Module PCB

Small OLED Display

Wireless Charger Receiver Module

2 Layer PCB Board

4 Layer PCB Board

6 Layer PCB Board

8 Layer PCB Board

Wireless Charger Coil

Mobile Phone Charging Lockers

Automatic Hand Sanitizer Dispenser Stand

Electromagnetic Solenoid Lock

Our Mission

------- Improve the quality of people's lives.

Our VisionOur Vision

------- To become a preferred choice of better living

experience.

Our Values

------- Excellence, innovation and respect constitutes our

culture for associates, business partners and customers. Each of us

is fully committed to serving our customers with good performance

and accomplishment what we do.